18

2020

-

06

How to install mineral cables?

Mineral-insulated cable is a type of cable where copper conductor cores are encased in a copper sheath, with magnesium oxide powder used as an inorganic insulating material to isolate the conductor from the sheath. The outermost layer can be a suitable protective sheath as required.

Mineral Insulated Cable A cable with copper conductor cores encased in a copper sheath, using magnesium oxide powder as an inorganic insulating material to isolate the conductor from the sheath. A suitable protective sheath can be selected for the outermost layer as needed.

Mineral Insulated Cable It has excellent high-temperature resistance and can also be used in tropical regions. At the same time, it also has good cold resistance and can be used in ultra-low temperature environments. It will not harden or break at low temperatures. This product has a high oxygen index, a small flame propagation range, and low smoke.

Mineral Insulated Cable Installation methods:

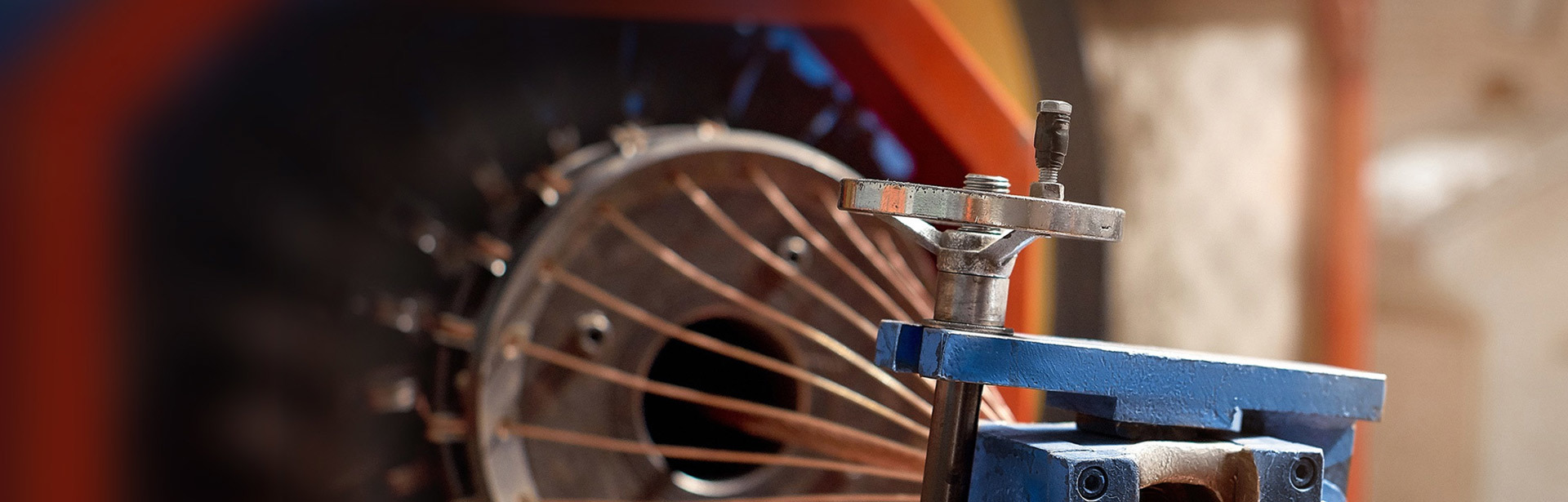

1. According to the required length, use a pipe cutter to cut a mark on the cable.

2. Use a diagonal cutting pliers to twist the copper sheath clockwise between the jaws, step by step clamping the edge of the copper sheath, and rotating and stripping the copper sheath at a small angle until the cut mark is reached.

3. Thoroughly clean the magnesium oxide insulation material from the exposed wires with a clean, dry cloth, then place the wire harness head on the cable and vertically screw the brass sealing cup onto the copper sheath of the cable sheath. At the beginning, twist by hand, slide the harness head on the sealing cup, and check the verticality of the sealing cup. After it is truly vertical, clamp the knurled seat of the sealing cup with a pipe wire clamp and continue installation until one end of the tiger skin is below the partial thread inside the sealing cup!

4. At the approximate distance, starting from the cable breaker, use a blowtorch flame to heat the cable 600 mm, and continuously move the flame to the open end of the cable to remove moisture. Remember to only move the flame to the open end of the cable, otherwise moisture will enter the cable.

5. Measure the insulation resistance between the iron cores and between the iron cores and the sheath with an ohmmeter. If the measurement results meet the requirements, the sealing compound can be injected into the sealing cup.

6. Note that the sealing compound should be added gradually from one side, not too fast, to exhaust air. When the sealing compound is completely filled, press down the cup cover, and then cover the core wire with a heat shrink tube.

Mineral cable, cable, power cable

Previous Page

Next Page

Previous Page

Next Page

Guangzhou Baiyun International Airport

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2021-04-13

Contact Us

Service Hotline

Address: Central Industrial Park, Luqiao District, Taizhou City, Zhejiang Province

Fax: 86-576-82670077