23

2020

-

07

Difference between mineral-insulated cables and ordinary cables

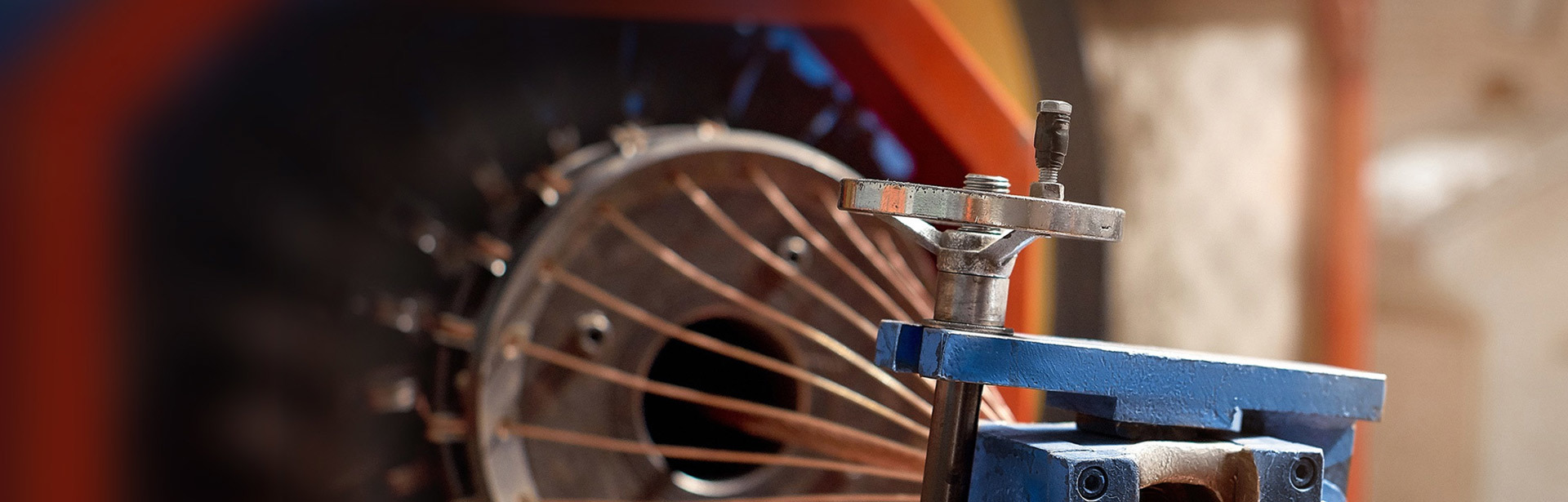

Mineral insulated cable intermediate connectors are used, and cable end terminals are used at the ends. The terminals have terminal boards that can be connected to the busbars and terminal boards of the equipment. Mineral insulated cables (MI cables), also known as magnesium oxide cables or fire-resistant cables in China, are copper-core copper-sheathed cables using magnesium oxide powder as insulation material. Mineral insulated cables consist of two inorganic materials: copper conductors, magnesium oxide, and copper sheathing. The differences between mineral insulated cables and ordinary cables are compared from the following aspects: I. Cable components

Mineral cable intermediate connectors are used, and cable end terminals are used at the ends. The terminals have terminal boards that can be connected to the busbars and terminal boards of the equipment.

Mineral Insulated Cable (hereinafter referred to as MI cable) is used as wiring cable. In China, it is usually called magnesium cable or fire-resistant cable. It is a copper-core copper-sheathed cable using magnesium oxide powder as the insulation material. Mineral insulated cables are composed of two inorganic materials: copper conductor, magnesium oxide, and copper sheath.

The differences between mineral cables and ordinary cables are compared from the following aspects.

I. Cable Assemblies

Ordinary cable: Copper core, plastic sheath.

II. Performance Comparison

Mineral cable : It will not burn, supports combustion, and does not produce harmful gases. It can maintain normal power supply for 3 hours at a flame temperature of 1000, has strong electrical stability, long service life, and large current carrying capacity.

Ordinary cable: Easy to burn and flame retardant, which will lead to harmful gases endangering lives. In case of fire, the escape system cannot be normally powered, the current carrying capacity is small, the maintenance cost is high, it is easy to age, and the service life is short.

III. Price Comparison

So, where do you need to use mineral cables?

If you like it, please follow Hongsheng Wire and Cable Co., Ltd., hoping to help everyone. Hongsheng Wire and Cable Co., Ltd. specializes in the production of mineral cables. The product quality is good and guaranteed. Welcome to negotiate!

Mineral cable

Guangzhou Baiyun International Airport

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2021-04-13

Contact Us

Service Hotline

Address: Central Industrial Park, Luqiao District, Taizhou City, Zhejiang Province

Fax: 86-576-82670077