06

2021

-

05

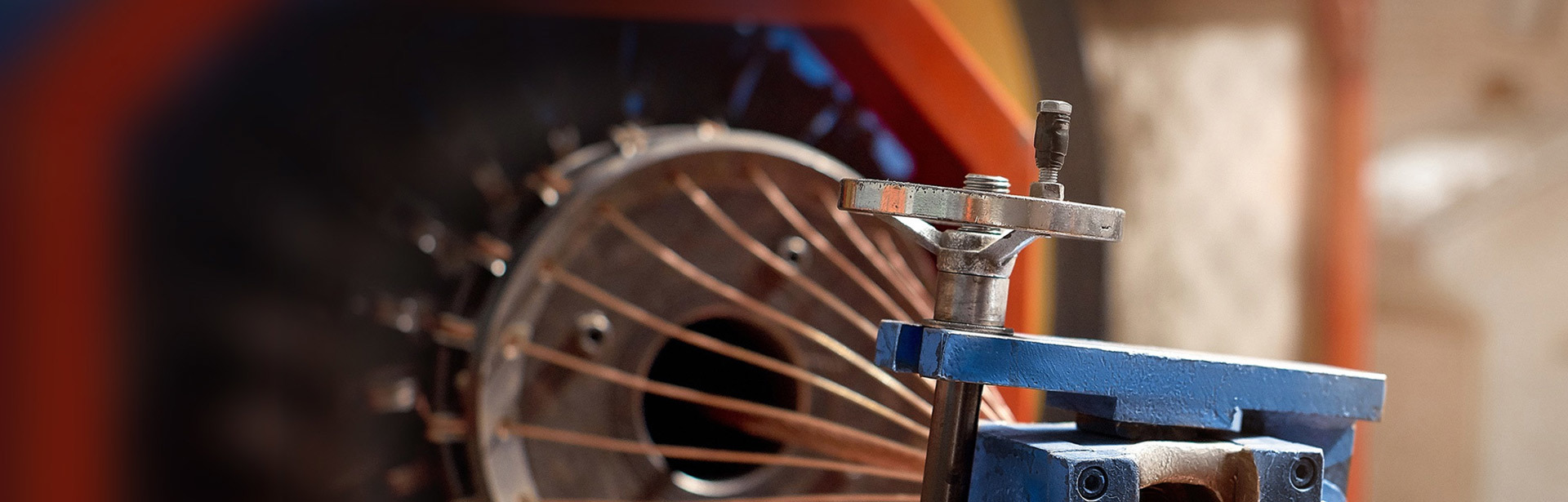

Copper core wire: Characteristics of copper core wire

Currently, all wires on the market use copper core wires, far exceeding aluminum core wires. Why is the market share of copper core wires so high? Jindi Cable claims the advantages of using copper core wires. 1. High strength: The allowable stress at room temperature is 7~28% higher for copper core wires than for aluminum wires. The difference is even greater at high temperatures.

Currently, all wires on the market use copper core wires , far exceeding aluminum core wires. Why is the market share of copper core wires so high? Jin Cable claims the advantages of using copper core wires.

1. High strength: Allowable stress at room temperature, copper core wires is higher than aluminum by 7~28%. Especially for stress at high temperatures, the difference between the two is even greater.

2. Fatigue relief: Aluminum material is easily broken by repeated bending, while copper material is not easily broken. The elasticity index of copper is 1.7-1.8 times higher than that of aluminum.

3. Good stability and corrosion resistance: Copper core can alleviate reactions, is corrosion-resistant, while aluminum core is easily oxidized and corroded.

4. Large carrying capacity: Due to its low resistivity, the allowable carrying capacity of copper core wires with the same cross-section is generally about 30% higher than that of aluminum core wires.

5、 Low resistivity: copper core wires The resistivity of is about 1.68 times that of copper core wire.

6. Good durability: Copper alloy promotion rate 20% to 40%, electro-copper promotion rate over 30%, aluminum alloy only 18%.

7. Convenient construction: 1. Copper core is flexible, allowing for a small bending radius, making it easy to bend and pass through pipes; 2. Copper core is easy to bend and not easily broken by repeated bending, making it easy to connect; 3. Copper core has high mechanical strength and can withstand greater mechanical tensile force, which greatly facilitates construction and laying, and also creates conditions for mechanized construction.

8. Low heating temperature: Under the same current, the heat generation of copper core wire with the same cross-section is much smaller than that of aluminum core wire, making it safer to operate.

9. Low voltage loss: Due to copper core wires low resistivity, under the same cross-section and the same working current. The voltage drop of copper core wire is small.

10. Slow reaction, corrosion resistance: copper core wires The joint performance is stable and will not cause accidents due to oxidation. The aluminum core wire joint is unstable and easily causes an increase in contact resistance and heat generation. Therefore, the accident rate is much higher than that of copper core wire.

11. Low energy consumption: Due to the low resistivity of copper, compared with aluminum wire, the power loss of copper wire is low, which is obvious. This helps to improve power generation efficiency and protect the environment.

Hongsheng Wire and Cable Co., Ltd. specializes in the production of power cables , copper core wires, wires 、 cables 、 copper core cables The product quality is good and guaranteed, welcome to negotiate!

Wire, copper core wire, copper core cable, power cable

Guangzhou Baiyun International Airport

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2017-09-13

2021-04-13

Contact Us

Service Hotline

Address: Central Industrial Park, Luqiao District, Taizhou City, Zhejiang Province

Fax: 86-576-82670077